The largest industrial heat cluster in Europe

The 30-million-euro project is part of a comprehensive decarbonization effort. The steam is produced at the Indaver and Sleco waste processing plant in Waasland Port, which is on the river Scheldt’s left bank in the Port of Antwerp. Five neighbouring energy-intensive chemical plants, ADPO, Ashland, Monument Chemical, Ineos Phenol and Lanxess, will use the steam in their production processes. This will allow them to reduce their energy bills by 10 to 20 percent. Containerterminal DP World-Antwerp Gateway will extract the heat from the return condensate duct.

Successful alliance

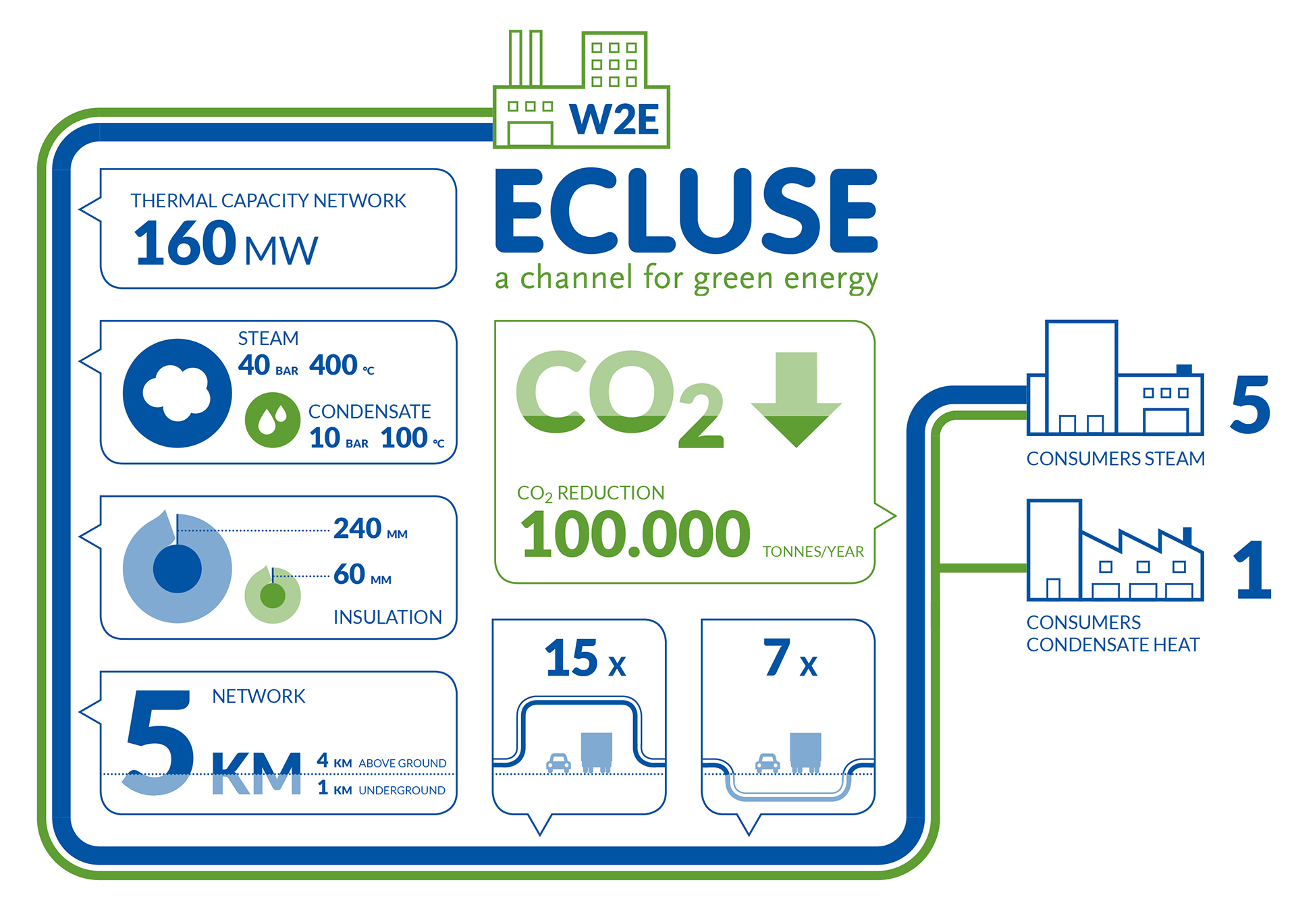

The 6-km pipeline currently being installed will transport steam at 400°C at a pressure of 40 bar. The ‘channel for green energy’ pipes are insulated with a 240-mm layer of rockwool and finished with an aluminium protective shield. Most of the pipes are above ground, with the expansion loops being clearly visible from nearby roads. Since half the waste treated in the waste-to-energy facility is bio-organic in nature, this proportion of the heat output can be considered 'green'.

ECLUSE is an alliance between Indaver, SLECO, Fluvius, FINEG, Water-Link and Maatschappij Linkerscheldeoever and has the support of the Belgian Federation for Chemistry and Life Science Industries, essenscia. The project has already won several awards, including the Integration Award at the 2018 CEWEP conference in Bilbao, organized by the European confederation of waste-to-energy plants.

Specifications

TCS designed and constructed the building housing the network’s 60,000-litre buffer vessel. “The turnkey project involved constructing pile foundations in difficult circumstances and co-ordinating several subcontractors to complete the project within the very short time span of two months,” says Indaver/SLECO Head of Projects and Modifications Jarne Van Meerbergen.

- 39 pile foundations

- 18 tonnes hot-dip galvanized steel

- 400 m² insulated steel wall panels

- 90 m² steeldeck, insulation and PVC roof

- 30 m² technical space with epoxy floor

- Floors and platforms

- 3 chain hoists 250/500 kg

Inspired by this story?